-

About Good Brothers Contact

-

01568 708 382

- enquiries@goodbros.co.uk

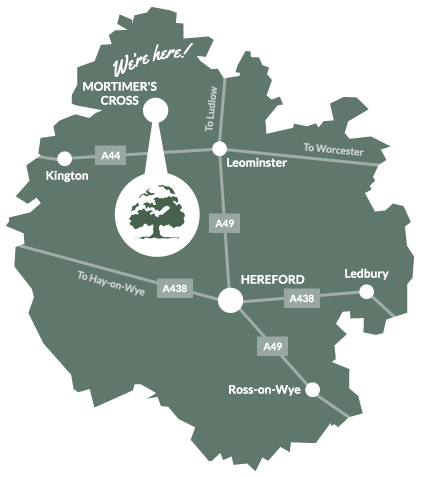

- Mortimer’s Cross, Herefordshire HR6 9TQ

About Good Brothers

Contact

About Good Brothers

Contact

01568 708 382

01568 708 382

About Good Brothers

Contact

About Good Brothers

Contact

01568 708 382

01568 708 382

Deep in the heart of the Herefordshire countryside.